Once various preparatory work such as asphalt cutting and our milling work has been completed, our BANKETTMASTER is deployed.

The BANKETTMASTER presses the concrete mass (in-situ concrete) via a screw conveyor into the slipform where the concrete is compacted, shaped and a groove profile is formed into the surface – all in a single operation. The BANKETTMASTER adapts the road shoulder to any road shape, regardless of whether it is a gradient, steep slope or tight bend. Our high-quality road banquette makes the issue of banquet renovation superfluous.

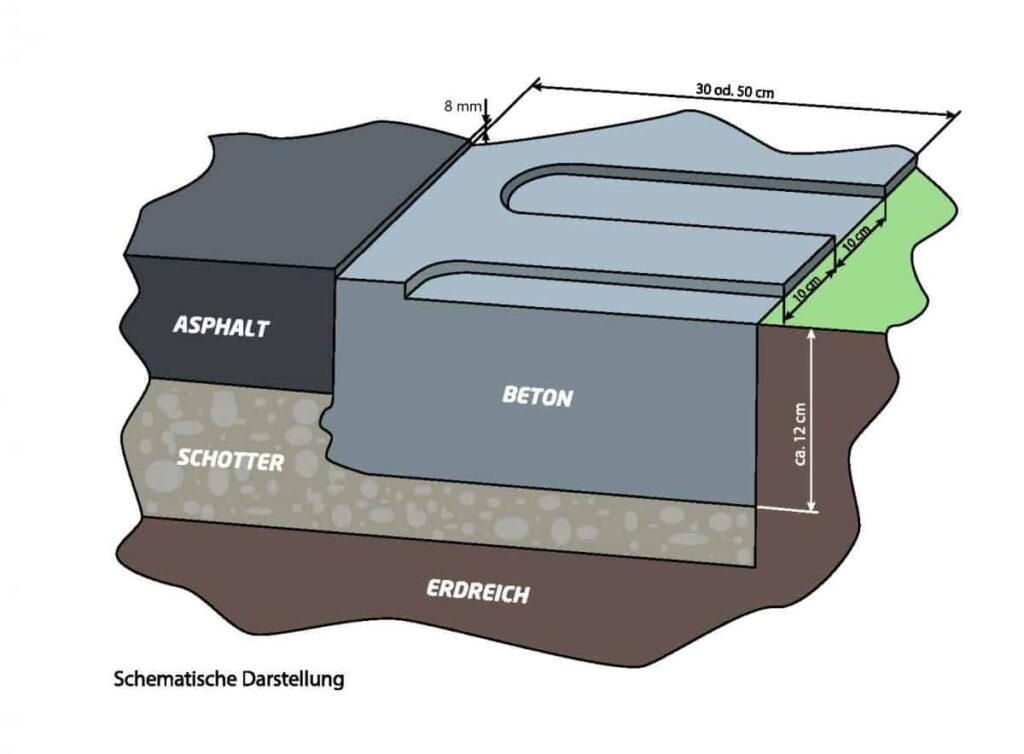

The verge can have a width of either 30 or 50 centimetres. The transverse grooves in the shoulder make it easier for water to flow off the road and have a high safety effect with regard to microsleep. If the sleeping driver hits the so-called rumble strip, the transverse grooves create a jolt that immediately wakes the driver.

Here comes the perfect technology for long-lasting roads: Feel the quality of high-density structural concrete as the key to unrivaled maintenance costs! Discover the sophisticated functionality with which BANKETTMASTER protects your roads from damage in the long term.

The unique verge is also safe to drive on. The embossed groove profile also warns you when you leave the actual roadway.

In the next section, we present the individual work steps in detail, which we carry out with the utmost care and precision in order to achieve the desired result.

We cut the

asphalt with precision and ensure perfect edges!

The milling machine crushes the separated asphalt cleanly and efficiently.

Efficient excavation and smooth loading onto trucks or trailers.

Our patented Banquetmaster 1901 creates the perfect banquet in no time at all.

Expansion joints are created at least every 25 LFM after the embankment has been constructed.

The finished banquette with grooved profile is durable, cost-effective and safe.